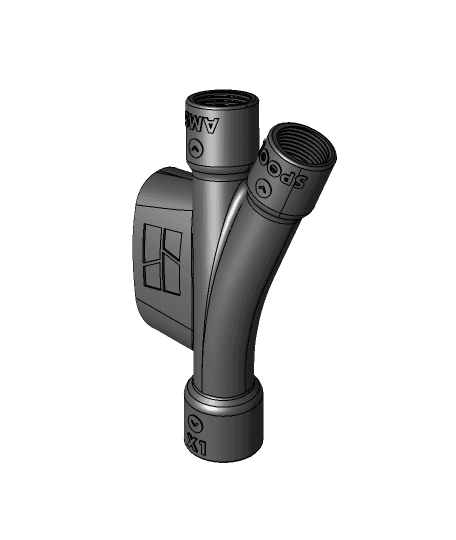

Bambu Lab Y-Splitter (5x5 magnets)

Description

This model allows all Bambu Lab X1/X1-Carbon users to use both the AMS and the external spool without having to disconnect/reconnect the PTFE tubes every time you want to switch. When designing this model I wanted to accomplish the below 3 goals:

-

Follow the filament's natural path for both AMS and external spool. The filament path in all available Y-Splitter designs is optimal only for the AMS. For the external spool, however, the splitter usually turns in an up direction, which can cause the filament to get snag when inserting it.

-

Relieve the strain on the toolhead PTFE Tube. This was achieved by adding a support section accommodating 3 neodymium magnets (5mm x 5mm). The Y-Splitter snaps nicely in place on the back cover of the printer.

-

**Remove the stock coupling. ** I wanted to reduce the weight and length of the whole setup. Since this model has pneumatic connectors on all 3 entries, the stock one isn't really required.

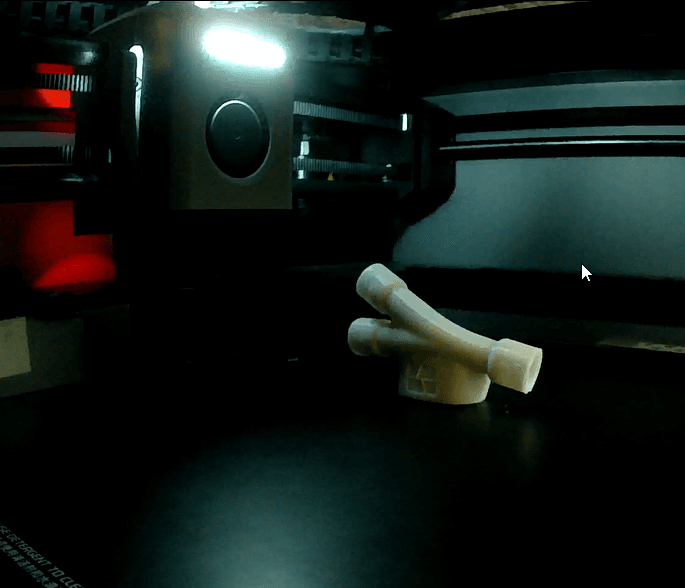

I have been using this Y-Splitter for over a week and can confirm it works beautifully. The AMS colour changes work effortlessly, and I am able to start a print with the external spool in a matter of seconds.

Print Settings

- Material: PETG (optimal) - PLA (best)

- Layer height: 0.08mm (optimal) - 0.12mm (best)

- Walls: 4 (highly recommended)

- Infill: 25%

- Infill pattern: Grid

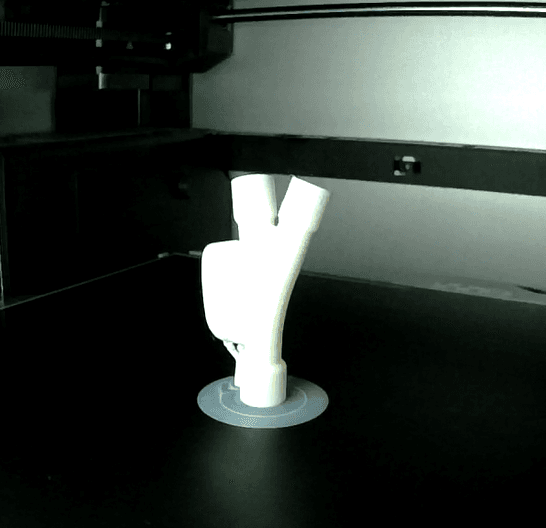

- Enable Support: YES

- Support Type: Tree (auto)

- Support Top Z distance: 0.45mm (this setting is to allow easy removal of the support)

- Support/object XY distance: 0.5mm (this setting is to allow easy removal of the support)

- Brim Type: Auto (highly recommended)

Bill of Materials

- 3 x PC4-M10 pneumatic connector

- 3 x neodymium magnets 5mm x 5mm

Important You need to adjust the toolhead PTFE tube to gain an additional 22mm so it sits flush inside the Y-Splitter. Alternatively, you can purchase a longer PTFE tube. If you decide to purchase a new one, ensure the ID is 2.5mm and the OD is 4mm.

I have moved the pneumatic stopper on the toolhead PTFE tube (the one sitting on the inside of the printer, next to the rubber sleeve where the PTFE tube exits the rear) and I can confirm that everything works perfectly fine. This option worked for me but may not for you so go print at your own risk. If you decide to go for this option, make sure the toolhead can reach the opposite corner and that the PTFE tube follows a natural path without any restrictions.

Disclaimer Avoid using any Carbon Fiber polymers (or any other abrasive options) to print this Y-Splitter since the roughness of the surface may cause the filament to get stuck on the inside path of the actual model.